Mechanical Devices Company Certifications

WBENC

WBENC Certification validates that the business is 51 percent owned, controlled, operated, and managed by a woman or women. To achieve WBENC Certification, women owned businesses complete a formal documentation and site visit process which is administered by one of WBENC’s 14 Regional Partner Organizations.

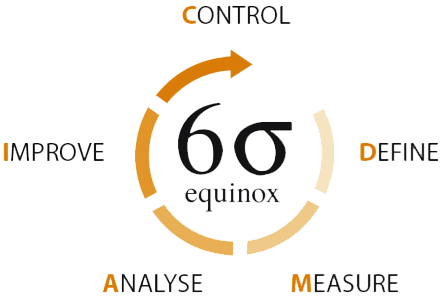

ISO 9001

ISO 9001 is the internationally recognized standard for establishing a quality management system. It is based on quality management principles that assure a customer-focused approach to design, development, production, installation and servicing of your order. It’s customer focus is recognized as enhancing satisfaction in the supplier-customer relationship. To earn ISO 9001:2008 certification, the quality management system is audited by ANAB accredited auditors. A multi-day audit covers all aspects our relationships with customers from quoting, though internal order processing, to shipment and service after delivery. After certification, systems continue to be internally and externally audited to assure our customers a mutually beneficial relationship consistent.

Corporate Quality Policy

Mechanical Devices is committed to the following principles:

To provide the highest quality manufacturing service possible to our customers through quality people and quality systems, through continuously improving the effectiveness of the quality management system and meeting or exceeding all customer requirements.

- WBENC (Women Owned Business) expires 03/31/2026

- WOSB (Women Owned Small Business) expires 03/31/2026

- ISO 9001 expires 03/28/2027

- DQS Inc. endorsement