Quality

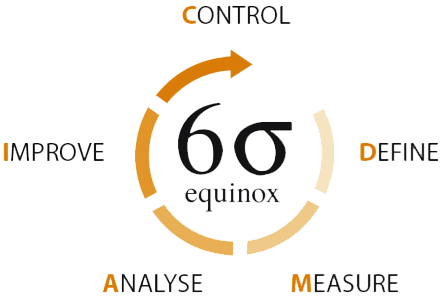

The quality and engineering staff takes a proactive approach to quality, when developing the entire process. The goal is to assure that only products that meet or exceed customer specifications are delivered to them. We utilize 6 Sigma methodology for problem solving and G8D for continuous corrective improvements for day to day quality. Our bar coding system allows us to control exact inventory levels and pre-plan production. Our production schedule operates at current plus three days. Our CMM probe inspections and pokey-yoke process ensures quality product with the removal of any human error. The quality of our products are world renown due to extensive testing . By continual preplanning, monitoring inventory levels, and testing, we are able to job cost and provide savings for our customers.

We utilize 6 Sigma methodology for problem solving and G8D for continuous corrective improvements for day to day quality. Our bar coding system allows us to control exact inventory levels and pre-plan production. Our production schedule operates at current plus three days. Our CMM probe inspections and pokey-yoke process ensures quality product with the removal of any human error. The quality of our products are world renown due to extensive testing . By continual preplanning, monitoring inventory levels, and testing, we are able to job cost and provide savings for our customers.

Mechanical Devices is proud to have multiple 6 Sigma Black Belts:

- Master Black Belt – 1

- Mechanical Devices Production System Black Belt – 1

- General Black Belts – 2