Mechanical Devices Company Services

By implementing a 5S program and operating with OEE efficiency, we eliminate waste and run a lean operational process at over an 85% optimum level. This saves both time and money for our customers. We also implement Sales and Operational Planning (S&OP) both internally and externally which allows us to demonstrate  performance for future production planning. S&OP sessions allow us to develop relationships with our customer establishing the same vested interest for success.

performance for future production planning. S&OP sessions allow us to develop relationships with our customer establishing the same vested interest for success.

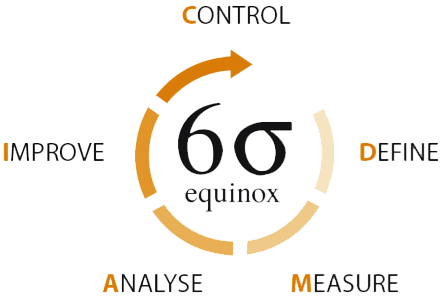

We utilize 6 Sigma methodology for problem solving and G8D for continuous corrective improvements for day to day quality. Our bar coding system allows us to control exact inventory levels and pre-plan production. Our production schedule operates at current plus three days. Our CMM probe inspections and pokey-yoke process ensures quality product with the removal of any human error. The quality of our products are world renown due to extensive testing such as pressure decay and millipour inspections we implement. By continual preplanning, monitoring inventory levels, and quality testing, we are able to job cost and provide savings for our customers.

Mechanical Devices Company has a separate receiving and shipping logistic operation equipped to support continued growth of the company for inventory and finished product shipment. Our Rough Cut Capacity Planning (RCCP) allows our operation to be proactive driven by facts and data for absolute accuracy when packaging for domestic or export. Inventory accuracy unitizing bar code technology, allows us to provide our customers with just in time shipping whether orders require one or one-hundred pieces.

Mechanical Devices Company strives to continually push for optimum quality management. With our dedication to quality, cost and shipping, is how we support our customers for a winning team of success.

Machining Processes

Mechanical Devices Company’s machining processes are developed to meet a vast array of customer needs. We have invested in cutting edge technology in order to stay current with the ever changing engineering and quality specifications. Our machining equipment includes the following:

- Horizontal Machining Centers (500MM to 1250MM)

- Vertical Machining Centers (DEM RANGE)

- Horizontal Turning (DEM RANGE)

- Vertical Turning (DEM RANGE)

Our facility has also incorporated additional machining processes to meet all requirements that a customer may request. With these additional processes, we ensure that we are the lowest cost producer, while managing effective on time delivery.

- Broaching

- Balancing

- Grinding

- Assembly

Finishing & Heat Treat Processes

Mechanical Devices Company takes a great deal of pride in partnering with high quality suppliers to provide the following customer requirements:

- Heat Treat

- Painting

- Plating

Supply Chain Management

Mechanical Devices manages the supply chain from rough material to Tier 1 purchase finish requirements on the majority of its business. We have strong business relationships with rough material suppliers that manage supplier profile, supplier development, packaging, inventory control, routine audits, strict quality requirements, on time PPAP submittal and modeling.

Our supplier base includes suppliers from within the United States as well as throughout North America and South America. By offering this service, we help our customers establish a competitive advantage by leveraging a global marketplace to deliver low costs while mitigating risks and insuring quality objectives are maintained.