Engineering

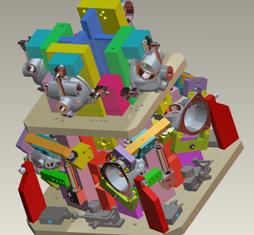

Mechanical Devices utilizes the Pro-Engineer™ CAD/CAM system to meet our internal  engineering requirements and those of our customers. Some common applications of our processes apply to forgings, bar stock and castings. The engineering staff plays an active role in product design using Design Failure Mode Effects Analysis (DFMEA) which assures the most cost-effective and error-proof manufacturing process. The team works closely with rough material suppliers to establish locator points to account for parting line and draft.

engineering requirements and those of our customers. Some common applications of our processes apply to forgings, bar stock and castings. The engineering staff plays an active role in product design using Design Failure Mode Effects Analysis (DFMEA) which assures the most cost-effective and error-proof manufacturing process. The team works closely with rough material suppliers to establish locator points to account for parting line and draft.

Our engineering team is also available to consult on fixture design to create a custom fixture for any companies manufacturing needs. Our engineering and tool making staff has the talent to design a wide variety of tooling applications including:

- Fixture Design

- Rapid Prototyping

- Customer Product Development

- Special Tooling Design

Mechanical Devices Company integrates advanced engineering into everything we do, including FMEA, Tool & Fixture design, casting design collaboration, Manufacturing process design, perishable tooling support and contract fixture building.

We integrate our engineering resources into key customer development teams at the earliest point possible to insure that customer quality, customer capacity requirements, casting, machining, and assembly design cost along with meeting customer cost objectives are integrated in the design prior to actual building the pattern, machine tooling, pressure test fixture and etc.

Our engineering program is designed to support both new jobs and engineering product design changes that meets ISO APQP and PPAP requirements. This service insures that quality is integrated into the product and process from the onset, maximizing potential for success for Mechanical Devices Company, our suppliers, its customers, and its extended supply chain team. Taking this approach on the onset reduces lead time for new job start up and has a proven history with our customers of excellence at the time rough material is processed to the final clean/pack logistic stage.